Description

In today’s demanding manufacturing landscape, ensuring optimal adhesion between dissimilar materials is critical to product performance and durability. ADMER Tie Resins for Superior Bonding offer an innovative solution to this challenge. Engineered by Mitsui Chemicals, ADMER is a family of modified polyolefin resins that act as outstanding adhesive layers in co-extruded structures, delivering consistent, durable bonding between polyolefins and various substrates like EVOH, PA, PET, and metals.

Designed for industries requiring superior barrier protection, mechanical strength, and multilayer integrity, ADMER enables manufacturers to achieve higher performance standards while optimizing production efficiency.

Key Features and Properties of ADMER Tie Resins for Superior Bonding

Exceptional Adhesion: Forms robust bonds between polyolefins (e.g., PE, PP) and polar materials (e.g., EVOH, PA, PET, metals).

Versatile Processing: Compatible with extrusion coating, film co-extrusion, blow molding, sheet extrusion, and pipe manufacturing.

Chemical Resistance: Maintains strong adhesion even under aggressive chemical environments.

Thermal Stability: Withstands elevated temperatures without loss of adhesion performance.

Customizable Grades: Available in a variety of formulations to suit different materials and processing methods.

Sustainability Support: Facilitates multilayer recycling and lightweighting initiatives.

Applications and Industries Served of ADMER Tie Resins for Superior Bonding

ADMER Tie Resins are trusted across a broad range of industries requiring multilayer construction, including:

Packaging Industry:

Food packaging (flexible and rigid)

Beverage containers

Pharmaceutical and medical packaging

Cosmetic tubes and pouches

Automotive Industry:

Fuel tanks

Brake and fuel lines

Multilayer pipes and ducts

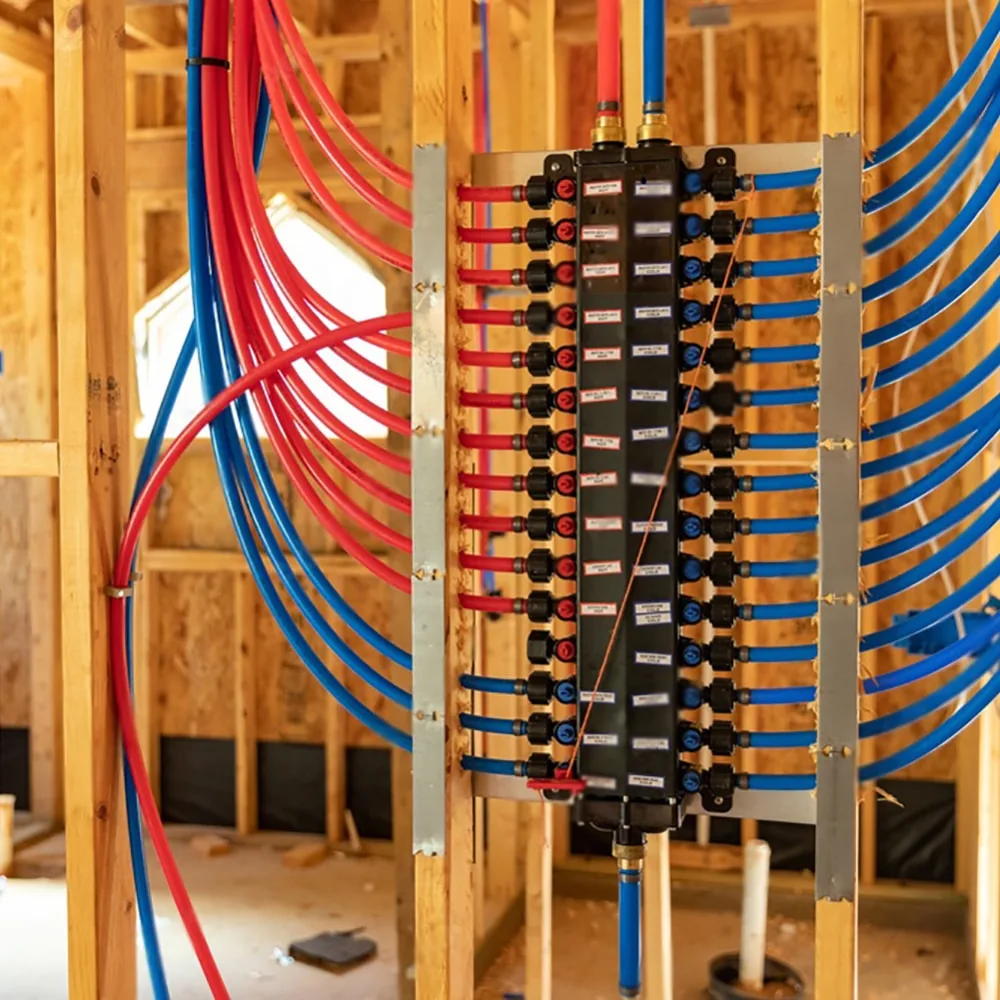

Construction Sector:

Multilayer composite pipes

Barrier sheets for insulation and protection

Industrial Applications:

Chemical-resistant containers

Industrial liners

Specialty laminates

By enabling reliable bonding in multilayer systems, ADMER contributes to the production of more durable, lightweight, and cost-effective solutions across these sectors.

Benefits and Competitive Advantages of ADMER Tie Resins for Superior Bonding

Enhanced Product Performance: Secure, lasting bonds improve the mechanical integrity and barrier properties of multilayer structures.

Production Efficiency: ADMER allows for streamlined manufacturing processes by eliminating the need for additional surface treatments or adhesives.

Design Flexibility: The wide range of available grades enables tailored solutions for diverse applications and processing conditions.

Cost Optimization: Reduces material waste and energy consumption through efficient co-extrusion and molding processes.

Sustainability Commitment: Supports recyclability of multilayer structures, aligning with global sustainability goals.

ADMER’s proven performance has made it a preferred solution among leading manufacturers who demand both quality and innovation.

Technical Information of ADMER Tie Resins for Superior Bonding

While detailed properties vary by specific grade, general specifications for ADMER Tie Resins include:

Base Polymer: Modified Polyethylene (PE) or Polypropylene (PP)

Melt Flow Rate (MFR): Ranges typically from 0.5 to 30 g/10 min (at 190°C/2.16 kg for PE-based grades)

Density: Approx. 0.92–0.95 g/cm³

Processing Temperatures:

Extrusion coating: 230–290°C

Blow molding: 190–230°C

Storage and Handling:

ADMER resins should be stored in a cool, dry place away from direct sunlight. Opened packages should be properly sealed to prevent moisture uptake.

Available Forms:

Pellets (standard form for industrial processing)

Certifications:

Food Contact Compliant (specific grades)

Automotive standards (select applications)

For full technical datasheets, processing guidelines, and regulatory compliance certificates, our team at A&D Polymers is ready to provide comprehensive support tailored to your project needs.