Description

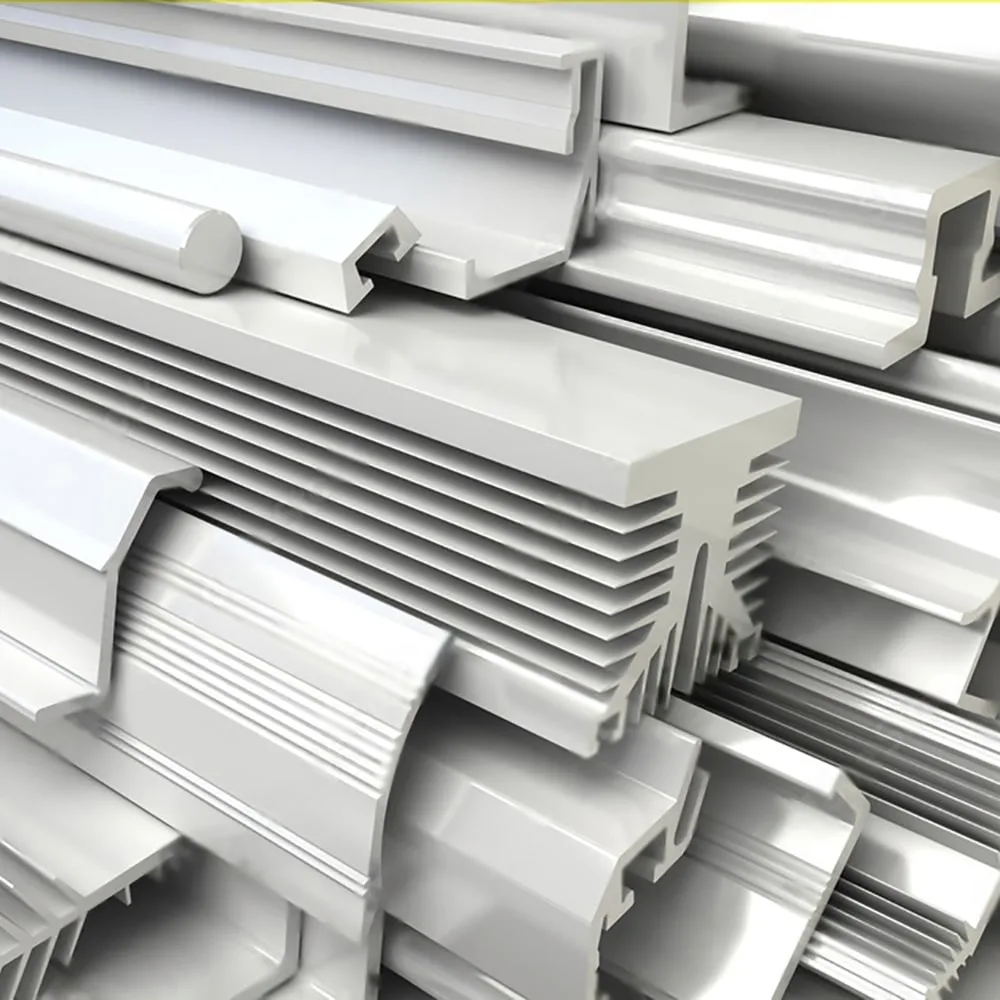

At A&D Polymers, we understand the critical role that processing aids play in achieving high-performance manufacturing results. Our Specialized Processing Aids are engineered to enhance the processability of plastics, rubber, and composite materials, ensuring smoother operations, better dispersion, and superior surface finishes. Designed with cutting-edge technology, these additives are tailored to meet the demanding requirements of industries such as automotive, construction, footwear, and packaging, where operational efficiency and product quality are non-negotiable.

Processing challenges such as poor melt flow, surface defects, and filler dispersion issues can significantly affect product quality and increase operational costs. A&D Polymers’ Specialized Processing Aids provide a dependable solution, minimizing these issues and empowering industries to achieve higher throughput, consistent quality, and reduced energy consumption.

Functional Properties

Our Specialized Processing Aids are formulated to deliver a wide range of critical enhancements during the production process:

Improved Melt Flow: Enhances the fluidity of polymers during extrusion, molding, and calendering processes.

Superior Dispersion: Promotes uniform distribution of fillers, pigments, and reinforcements within the polymer matrix.

Surface Quality Enhancement: Minimizes defects like die lines, surface roughness, and haze, delivering aesthetically superior products.

Reduction in Processing Temperature: Facilitates lower processing temperatures, resulting in energy savings and reduced thermal degradation.

Decreased Cycle Times: Enables faster production cycles through better flow and release properties.

Compatibility: Designed for a broad range of thermoplastics, elastomers, and composites.

Areas of Application

Specialized Processing Aids find applications across a broad spectrum of industries, including:

Automotive: Enhancing surface appearance and durability of interior and exterior plastic components.

Construction: Improving flow and consistency in profiles, pipes, and fittings.

Footwear: Enabling efficient molding and finish quality in shoe soles and components.

Packaging: Facilitating high-speed production and achieving superior clarity and surface finish for films, containers, and closures.

Recycling: Assisting in reprocessing recycled plastics by improving melt flow and blend uniformity.

Electronics: Enhancing the molding precision of housings and insulation components.

Key Benefits and Performance Enhancements

Choosing A&D Polymers’ Specialized Processing Aids offers a strategic advantage:

Operational Efficiency: Reduced energy use, faster cycle times, and minimized equipment wear.

Material Cost Savings: Enhanced flow and dispersion allow for higher filler loading without compromising quality, leading to material cost savings.

Quality Consistency: Improved product uniformity across batches reduces rework and scrap rates.

Enhanced Product Performance: Superior mechanical properties, improved surface finishes, and consistent color distribution.

Process Flexibility: Supports a wider processing window, allowing manufacturers to operate under varying conditions without compromising quality.

Our commitment extends beyond supplying additives—we provide customized technical support to ensure optimal integration and performance of our processing aids in your specific production environment.

Technical Characteristics

Depending on the selected formulation, A&D Polymers’ Specialized Processing Aids offer:

Physical Form: Powder, pellet, or masterbatch formats

Compatibility: Tailored for polyolefins (PE, PP), PVC, TPEs, TPUs, nylons, and elastomers

Effective Dosage: Typically between 0.5% to 3% depending on the polymer system and desired effect

Thermal Stability: High resistance to processing temperatures up to 300°C

Regulatory Compliance: Many grades compliant with REACH, RoHS, and food contact standards (specific grades available upon request)

Conclusion

A&D Polymers’ Specialized Processing Aids exemplify our dedication to delivering innovative, sustainable, and high-performance solutions. Whether your goal is to streamline production, enhance product aesthetics, reduce operational costs, or tackle specific processing challenges, our processing aids offer a reliable path to achieving and exceeding your production targets.

Partner with A&D Polymers to unlock the full potential of your manufacturing processes through expert material selection, customized support, and cutting-edge additives that push the boundaries of performance.